Tube Manipulation Companies

Need Tube Manipulation?

Make Sure You Contact Us!

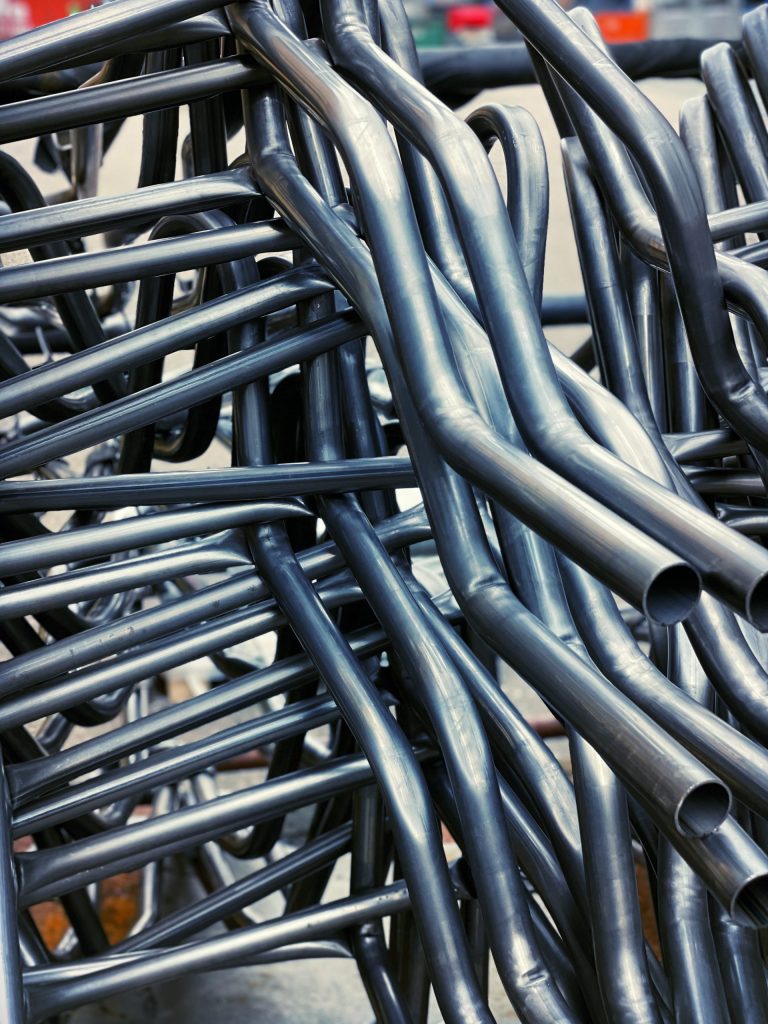

At Threeway Pressings, we specialise in offering exceptional tube manipulation services relied upon by industries ranging from automotive to aerospace, construction, and beyond. Our advanced techniques, coupled with decades of experience, ensure we can manipulate and form tubes to precise specifications, maintaining high levels of quality, consistency, and durability.

Tube manipulation involves the careful process of shaping and altering tube sections to meet specific requirements. Whether it’s bending, flaring, swaging, or end forming, Threeway Pressings has the expertise needed to manage these processes efficiently. If you require tubes that fit perfectly into your assembly, system, or product, we can make it happen!

ISO 9001:2015

ISO 9001:2015 is a globally recognised standard for quality management systems (QMS) for a variety of organisations.

5 Axis Longbow CNC

This level of flexibility allows for the production of highly complex and intricate parts with greater efficiency

Up to 30mm

Capability to manipulate both round and square tubes in a diverse range of diameters, with capacities of up to 30mm

In-House Tooling

In-house tooling refers to the capability of a company to design, manufacture, and maintain its own tooling or moulds used in the production process.

Why Choose Us When You’re Looking For Tube Manipulation Companies?

Threeway Pressings offers a unique advantage to businesses in need of tube manipulation services. Our state-of-the-art equipment and skilled team of technicians enable us to work on a wide range of applications using materials such as stainless steel, aluminium, copper, and brass.

Here are just some of the reasons why you should choose us:

Comprehensive Service Offerings: From simple tube bending to complex swaging and forming, we offer a full suite of tube manipulation processes to ensure that we can handle any requirements. Whether it’s for small or large-scale projects, Threeway Pressings is equipped to meet your demands!

Cutting-Edge Technology: We leverage advanced machinery and tools designed for tube manipulation, such as CNC-controlled bending machines, end-forming equipment, and swaging tools. This helps us produce intricate designs and deliver high-quality results consistently.

Quality Assurance: We pride ourselves on delivering top-quality tube manipulation services! Each project undergoes stringent quality checks to ensure that it meets all required standards and specifications. We understand that precision is paramount, and our customers know they can trust us to deliver reliable and accurate results every time.

Extensive Industry Experience: With years of experience working with industries such as automotive, manufacturing, construction, and aerospace, we know the specific needs and challenges of each sector.

Customisation And Flexibility: We understand that every project has unique requirements. Whether you need short-run batches or high-volume production, we can adapt to your needs and deliver precisely the type of tube manipulation your project demands.

About Our Tube Manipulation Facilities

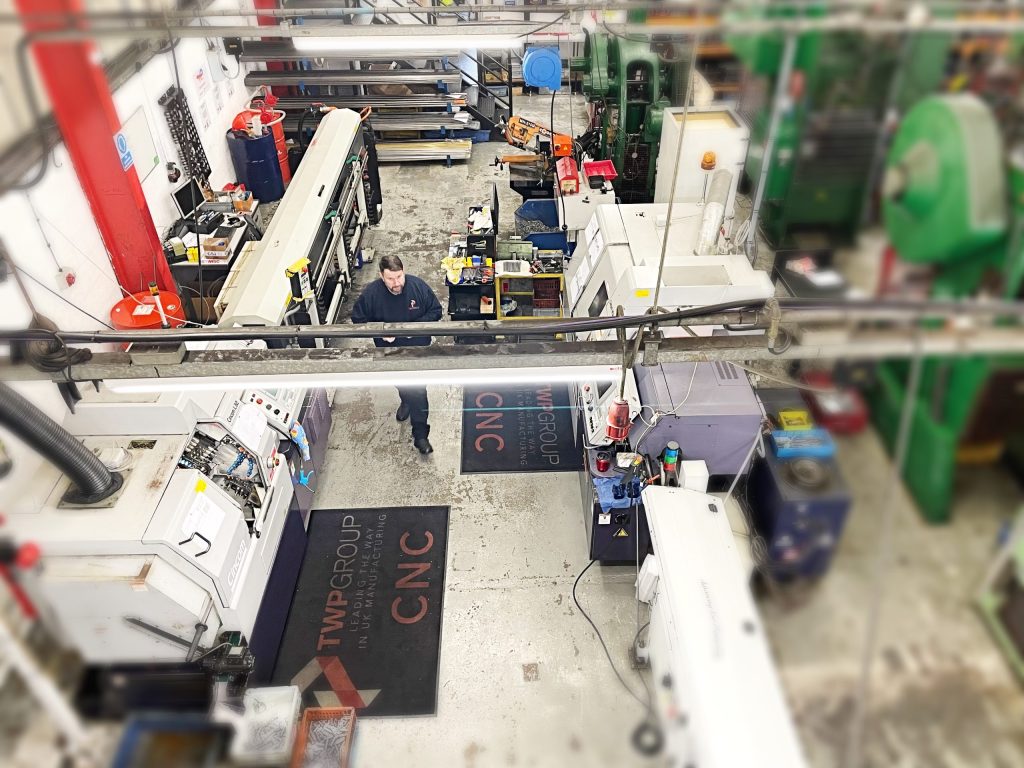

The 5-axis Longbow CNC is an advanced computer numerical control (CNC) machine specifically designed for precision tube bending operations. It offers enhanced capabilities compared to traditional 3-axis or 4-axis machines by incorporating two additional axes of movement, providing greater flexibility and control over the bending process.

The term “5-axis” refers to the machine’s ability to move the tube along five different axes: X, Y, Z, as well as two rotational axes, typically referred to as A and B axes. This multi-axis movement enables the Longbow CNC to manipulate the tube in a more versatile manner, allowing for complex and intricate bends with high accuracy.

The Longbow CNC machine is equipped with advanced features and cutting-edge technology to ensure precise and efficient tube bending. It utilises sophisticated software and programming capabilities to generate complex tool paths, optimising the bending process and minimising errors.

Tube Manipulation With TWP

With the 5-axis Longbow CNC, operators can perform a wide range of tube bending operations, including intricate shapes, compound bends, and multi-plane bends. This level of versatility and precision makes it particularly suitable for applications that require complex tube geometries or tight tolerances, such as in the aerospace, automotive, and medical industries.

By leveraging the capabilities of the 5-axis Longbow CNC machine, TWP Manufacturing can deliver exceptional tube bending results, meeting the demanding requirements of various industries and providing customers with high-quality, precisely formed tube components.

Our Tube Manipulation Processes

At Threeway Pressings, we use a variety of tube manipulation processes to meet the needs of our diverse clientele. Here are some of the most common methods we employ:

Tube Bending

Tube bending is one of the most commonly requested services we offer. It involves bending tubes to a specific angle, shape, or radius without compromising the integrity of the material. Our CNC-controlled tube benders ensure that bends are accurate and consistent, with tight tolerances.

Whether it’s for a one-off project or high-volume production, our bending service can handle various tube materials and diameters, including thin-walled, thick-walled, and large-diameter tubes.

We’re capable of producing bends up to 180° with excellent repeatability, making us the ideal partner for automotive exhaust systems, air conditioning units, structural frameworks, and more.

Tube End Forming

Tube end forming is a process that changes the shape of the ends of tubes to fit other components. This is commonly used in industries like automotive, plumbing, and HVAC systems. The end forming process can be as simple as adding a chamfer or as complex as flaring or reducing the tube’s diameter.

We use various end-forming methods, including:

Flaring: Expanding the end of the tube to create a wider opening, useful in fitting and connecting pipes or tubes.

Swaging: Compressing the tube to a smaller diameter at one end, ideal for fitting or joining with other components.

Beading: Creating a raised ring or bead along the length of the tube to provide a stronger joint or better sealing properties.

Punching: Creating holes or perforations in tubes for various purposes, such as ventilation systems.

Whether your end-forming requirements are simple or intricate, our skilled engineers are ready to provide precisely what you need.

Tube Swaging

Swaging involves reducing the diameter of a tube using a specific die and pressure. This process is typically used for creating smaller sections or to fit components like fittings, plugs, or inserts. It’s ideal for creating strong, secure joints in tubes or modifying the tube for a custom purpose.

Our swaging process is suitable for both soft and hard metals, ensuring compatibility with a variety of applications. Swaged ends are highly precise and offer excellent strength, ensuring long-lasting performance even under high stress.

Rotary Drawing

Rotary drawing is a process used to reduce the diameter of a tube or pipe while also increasing its length. This process is ideal when precise control is required to reduce the diameter without thinning the material excessively.

Rotary drawing is particularly effective for tubes used in applications that require high levels of precision, such as in the production of medical instruments, aerospace components, and other highly specialised products.

Tube Expansion

Tube expansion is a tube manipulation technique that involves increasing the diameter of a tube to fit over a larger pipe or component. This is useful in various industries such as refrigeration, air conditioning, and heating systems.

Our tube expansion process guarantees an exact fit, enabling components to be securely connected and creating long-lasting and robust systems.

The Materials We Work With

We offer tube manipulation services using a wide range of materials to accommodate the diverse needs of our clients. Whether your project requires a lightweight material for ease of handling or a strong, corrosion-resistant alloy for demanding environments, we can work with all of the following:

Stainless Steel: Known for its durability and resistance to corrosion, stainless steel tubes are commonly used in industries such as food processing, pharmaceuticals, and automotive manufacturing.

Aluminium: Lightweight and malleable, aluminium tubes are often chosen for applications in aerospace, automotive, and general engineering.

Copper: Widely used in plumbing and HVAC systems, copper tubes are a popular choice for systems requiring excellent thermal conductivity and corrosion resistance.

Brass: Brass tubes are favoured in marine and electrical applications due to their strength and resistance to corrosion.

Regardless of the material you choose, Threeway Pressings ensures that the manipulation process doesn’t compromise the quality or structural integrity of the tube, resulting in a high-quality finished product every time.

The Benefits Of Tube Manipulation

Tube manipulation plays a crucial role in a wide range of industries and applications, offering flexibility in how tubes can be shaped to meet specific design or functional requirements. Whether you’re designing custom mechanical assemblies, exhaust systems, or specialised fluid transfer systems, tube manipulation offers several key benefits:

Cost-Effective Solutions: Tube manipulation can help reduce material waste by enabling precise cuts, bends, and end forms. Additionally, by creating custom shapes or sizes, businesses can avoid the need for costly bespoke components or specialised fittings.

Improved Performance: By manipulating tubes to fit perfectly into their designated systems, tube manipulation ensures that all components function together seamlessly, improving overall performance and efficiency.

Enhanced Aesthetics: Tube manipulation is not only functional but can also enhance the visual appeal of products. A well-designed tube assembly adds professionalism and a sleek finish to the final product.

Contact Us If You’re Looking For Tube Manipulation Companies!

At Threeway Pressings, we take great pride in offering the highest level of tube manipulation services, tailored to meet your exact needs. Whether you’re working on a small prototype or a large-scale production, our skilled technicians and cutting-edge equipment can provide you with the precise solutions you need.

If you’re looking for a reliable partner to help with tube manipulation, look no further than Threeway Pressings. Get in touch with us today to discuss your project and discover how our services can benefit you.

We’re ready to offer our expertise, work closely with you, and deliver the results you need—on time and on budget.

Want to find out more?

TWP Manufacturing can deliver exceptional tube bending results, meeting the demanding requirements of various industries. Click on the button below to start your manufacturing journey with TWP Manufacturing.