CNC Machining

CNC Machining With TWP

TWP Manufacturing utilises advanced Sliding Head CNC machines, which offer exceptional precision and efficiency in the manufacturing process. These machines are highly versatile and provide several advantages over conventional CNC machines.

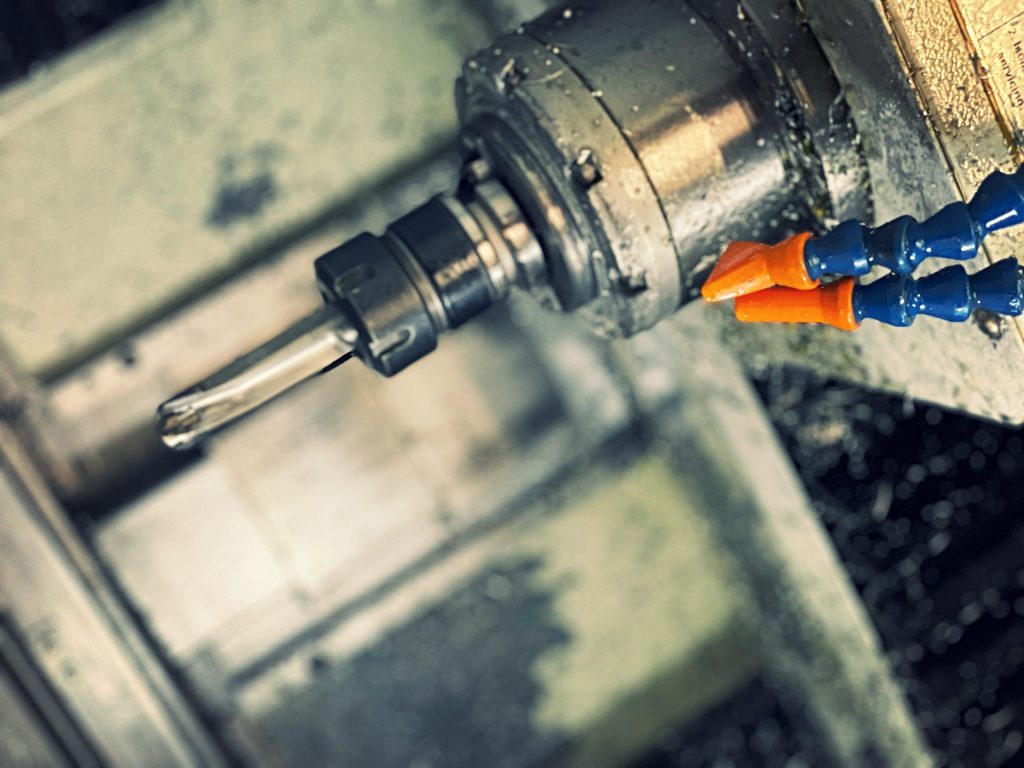

The Sliding Head CNC machines are specifically designed for complex and intricate machining operations, particularly for long and slender components. They feature a sliding headstock that holds the bar stock material firmly in place while allowing the cutting tools to access multiple angles and positions with high precision.

ISO 9001:2015

ISO 9001:2015 is a globally recognised standard for quality management systems (QMS) for a variety of organisations.

CNC Machining

CNC Machining for various materials for Automotive and Aerospace industries.

Sliding Head

One of the key advantages of Sliding Head CNC machines is their ability to perform simultaneous multi-axis machining. With the incorporation of multiple tool stations.

In-House Tooling

In-house tooling refers to the capability of a company to design, manufacture, and maintain its own tooling or moulds used in the production process.

TWP Manufacturing - CNC Machining

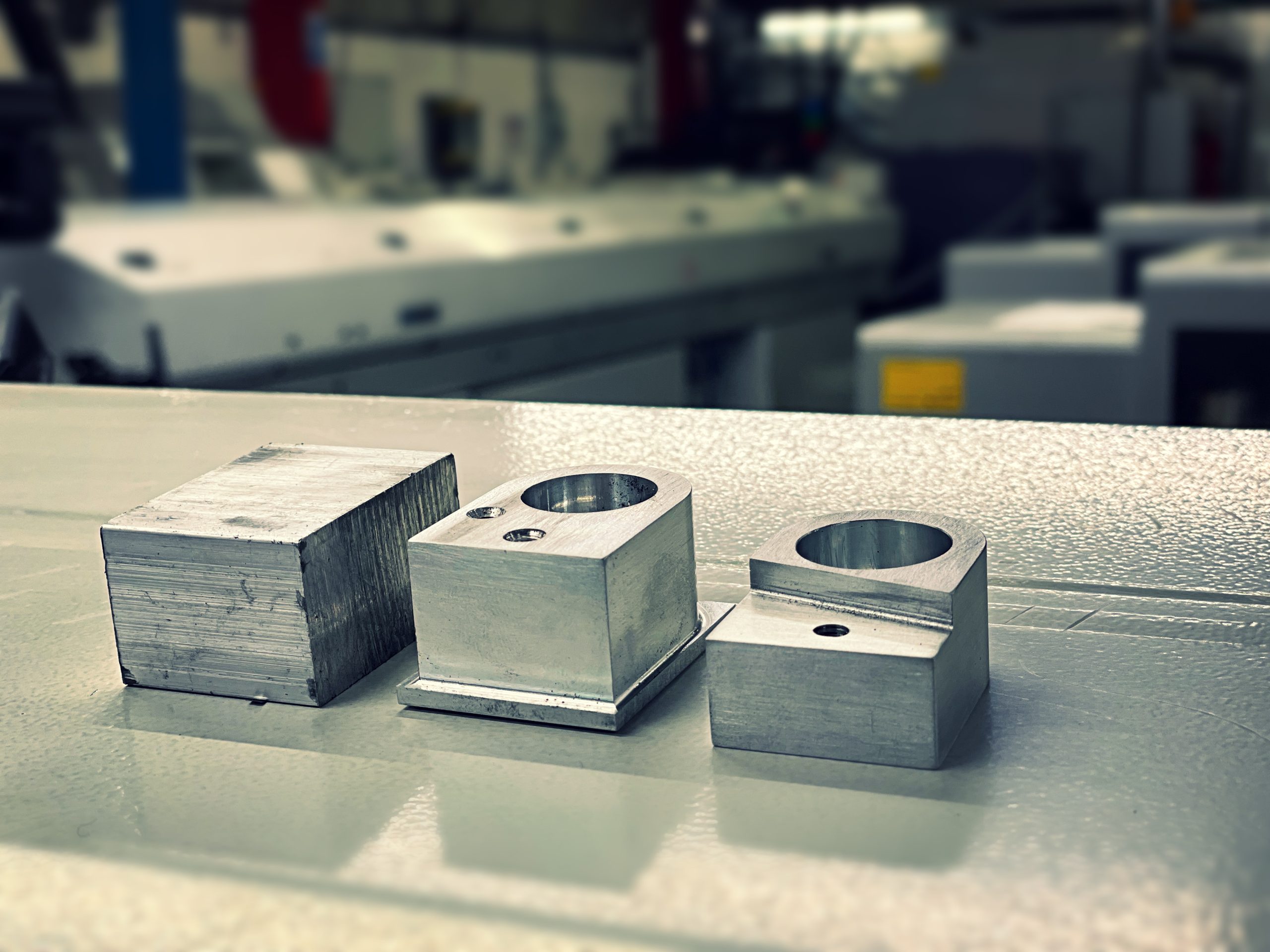

One of the key advantages of Sliding Head CNC machines is their ability to perform simultaneous multi-axis machining. With the incorporation of multiple tool stations and axes of movement, these machines can execute various operations in a single setup. This reduces the need for manual intervention and multiple machine setups, resulting in improved efficiency and reduced cycle times.

The machines excel in high-volume production due to their fast and continuous machining capabilities. They can rapidly produce components with high accuracy and repeatability, enabling efficient manufacturing of large quantities while maintaining consistent quality.

Sliding Head CNC machines are known for their superior accuracy and surface finish. With precise control over cutting forces and minimized vibration, they can achieve tight tolerances and excellent surface quality on complex geometries. This makes them particularly suitable for industries with stringent quality requirements, such as automotive, aerospace, and medical sectors.

TWP Manufacturing - CNC Machining

The sliding headstock design of these machines also provides optimal access to the workpiece, allowing for efficient chip evacuation and reducing the risk of tool interference. This enhances overall productivity and enables the machining of intricate features without compromising accuracy or surface finish.

Moreover, Sliding Head CNC machines offer the flexibility to work with a wide range of materials, including metals and plastics. They can handle bar stock of various diameters, allowing for versatility in component design and production.

At TWP Manufacturing, our skilled engineers and operators leverage the capabilities of Sliding Head CNC machines to deliver high-quality components with exceptional precision and efficiency. Through efficient multi-axis machining, reduced setup times, and superior surface finish, we strive to meet the diverse needs of our customers and provide them with optimal manufacturing solutions.

Want to find out more?

To help take away the pain of CNC Machining TWP Manufacturing can assist. Click on the button below to start your manufacturing journey with TWP Manufacturing.