Plastic Injection Moulds Manufacturer

Need A Top-Quality Plastic Injection Mould Manufacturer?

Make Sure You Contact Us!

At Threeway Pressings, we take pride in being one of the leading plastic injection mould manufacturers in the UK, delivering high-quality plastic injection moulding services known throughout the country for their precision, durability, and cost-effectiveness.

With years of experience and cutting-edge technology, we serve a wide variety of industries while ensuring that every product meets the highest quality and performance standards.

What Does A Plastic Injection Moulds Manufacturer Do?

Plastic injection moulding is a process where molten plastic is injected into a mould cavity under high pressure, then solidifies as it cools, taking the shape of the cavity.

This method is perfect for producing high volumes of precise, consistent parts, making it a popular choice for industries like automotive, electronics, and consumer goods.

Thanks to its versatility and efficiency, plastic injection moulding is ideal for companies that need reliable, cost-effective manufacturing solutions.

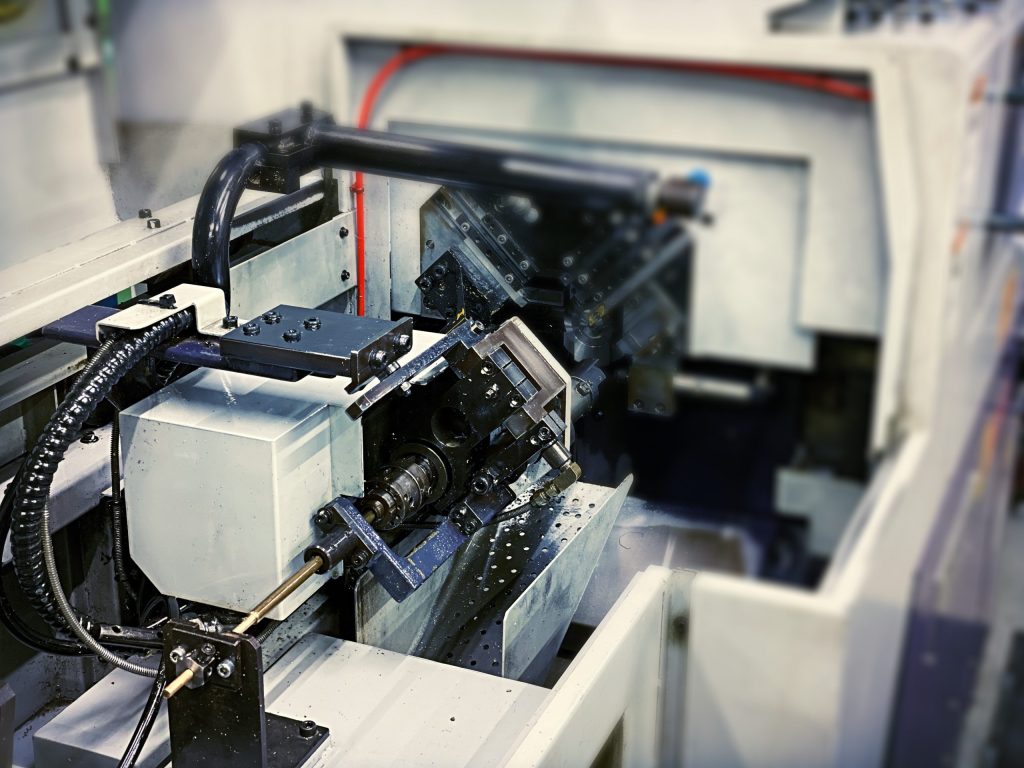

Expertise And Technology At Threeway Pressings

At Threeway Pressings, we have a wide range of plastic injection moulding machines, from small to large tonnage, allowing us to create both small, intricate components and larger, more complex parts. Plus, our experienced team is skilled in working with a variety of plastics to ensure we select the best option for your needs.

From tool design to material selection, we partner with you every step of the way, ensuring that your product is manufactured to the highest standards. Our engineers are on hand from the initial design phase, providing expert advice on mould design, plastic choice, and any factors that could impact the final product.

We Are A Top-Quality Plastic Injection Mould Manufacturer!

A primary benefit of injection moulding is the ability to produce parts in large quantities without sacrificing quality.

At Threeway Pressings, we’re committed to maintaining precision and consistency throughout the process, thereby reducing waste, and improving efficiency. Whether you need a few hundred or several million units, we tailor our plastic injection moulding services to meet your needs, delivering high-quality products at competitive prices.

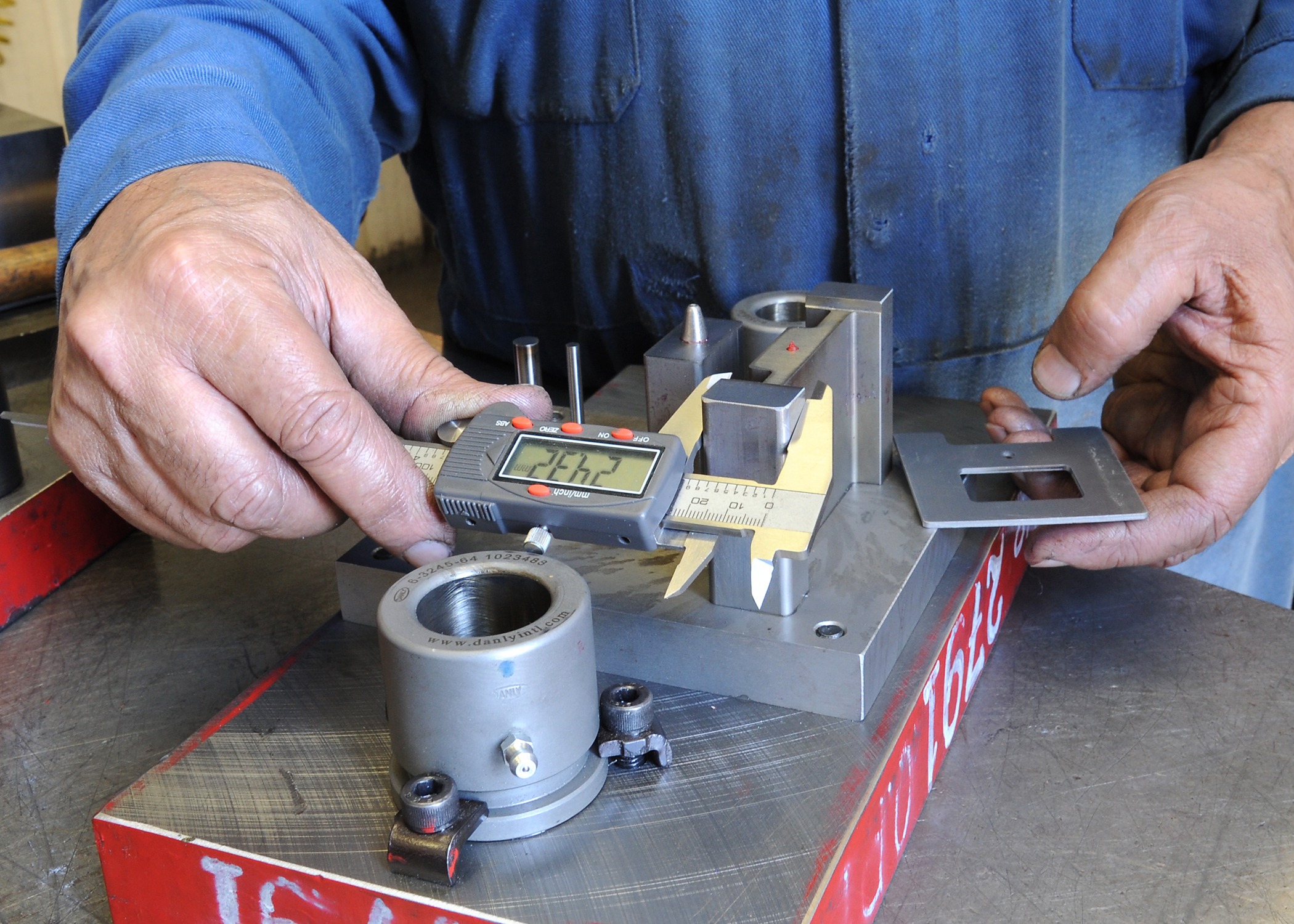

Plus, our rigorous quality control ensures that each product meets the project’s specifications at every stage, from the prototype to the final product.

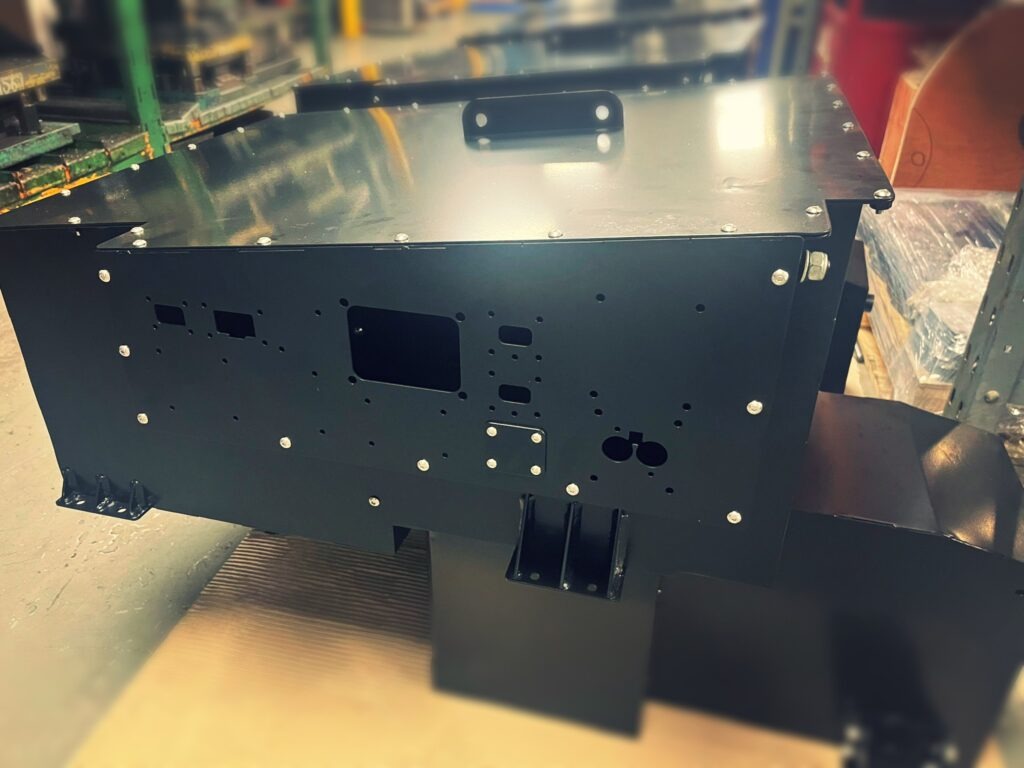

Custom Tooling And Mould Design

Custom tooling and moulds are key to the versatility of plastic injection moulding.

At Threeway Pressings, our in-house tooling team works closely with our design and engineering experts to create moulds that match your exact specifications. We collaborate with you to understand your requirements, ensuring that every detail is captured in the design.

From initial designs to prototyping, we help refine your product to ensure it’s optimised for the injection moulding process. Our custom tooling helps ensure that manufacturing runs smoothly and efficiently, keeping both time and costs down.

Overmoulding Capabilities

Overmoulding is the process of moulding one material over another to create a composite part. It’s especially useful for products that need added features like grips, seals, or multi-material components.

We offer overmoulding capabilities, allowing us to create complex, multi-material parts in a single process. This not only enhances your product’s functionality but also improves its aesthetic appeal and durability.

Whether you’re making automotive, medical, or consumer products, our overmoulding services can meet your needs with precision and quality.

Secondary Operations For Customisation

Alongside our core injection moulding services, we offer several secondary operations to add value to your products.

These include insert moulding, laser engraving, and ultrasonic welding, which let us add features like logos, text, and assembly components to your parts, increasing their functionality and customisation.

For example, laser engraving provides high-precision markings ideal for branding or part identification, while insert moulding allows us to add materials like metal inserts into plastic components, enhancing strength and durability.

These secondary services are part of our comprehensive injection moulding offerings, helping you achieve the perfect product.

Sustainability And Material Selection

Sustainability is a key priority in all our processes, including plastic injection moulding.

We work with a range of eco-friendly and recyclable plastics, ensuring that our manufacturing processes are environmentally responsible. Our team can guide you on the best choices for your project, balancing cost, durability, and sustainability

By prioritising responsible material selection, we help create high-quality products that meet your environmental goals while providing the performance you need!

The Industries We Serve

Threeway Pressings provides high-quality plastic injection moulding services across a broad range of industries. We tailor our services to meet the unique demands of sectors like automotive, medical devices, electronics, and consumer goods.

For instance, in the automotive industry, we produce parts that meet stringent standards for performance, safety, and durability.

In the medical sector, we ensure compliance with regulatory standards, delivering components that are safe and reliable.

And for consumer goods and electronics, we focus on creating high-quality, visually appealing products that enhance user experience.

Whether you’re looking for precision components or large-scale production, we’re here to help. Get in touch today to learn more!

Why Choose Us To Be Your Plastic Injection Mould Manufacturer?

There are many reasons why customers trust us with their plastic injection moulding needs. These include:

- Customisation And Flexibility: Whether you need a small batch or a large production run, we tailor our services to meet your specific needs.

- Expertise And Experience: With years of industry experience, our team has the knowledge to handle projects of all sizes.

- State-of-the-Art Technology: Our advanced machinery and tooling enable us to produce precise, high-quality parts quickly.

- Rigorous Quality Control: We maintain strict quality control processes, ensuring every part meets the highest standards.

- Cost-Effectiveness: Our efficient processes and competitive pricing deliver top-quality products at affordable rates.

At Threeway Pressings, we offer a full range of plastic injection moulding services designed to meet the needs of a variety of industries.

From custom tooling to overmoulding and secondary operations, we provide a comprehensive solution to all your manufacturing requirements.