Metal Pressings UK

Metal Pressings UK

Looking For Top-Quality Metal Presswork?

Make Sure You Contact Us!

At Threeway Pressings, we are leading UK-based manufacturers specialising in high-quality metal presswork, fabrications, and assemblies.

With decades of experience in the industry, we provide precision-engineered metal components for various sectors, including automotive, aerospace, medical, and industrial applications.

Our expertise in metal pressings ensures that clients receive durable, accurate, and cost-effective solutions tailored to their specific requirements!

What Is Metal Presswork?

Metal pressings, also known as metal stampings, involve shaping flat metal sheets into desired forms using high-pressure presses and dies. This process is highly efficient for producing large volumes of components with consistent quality.

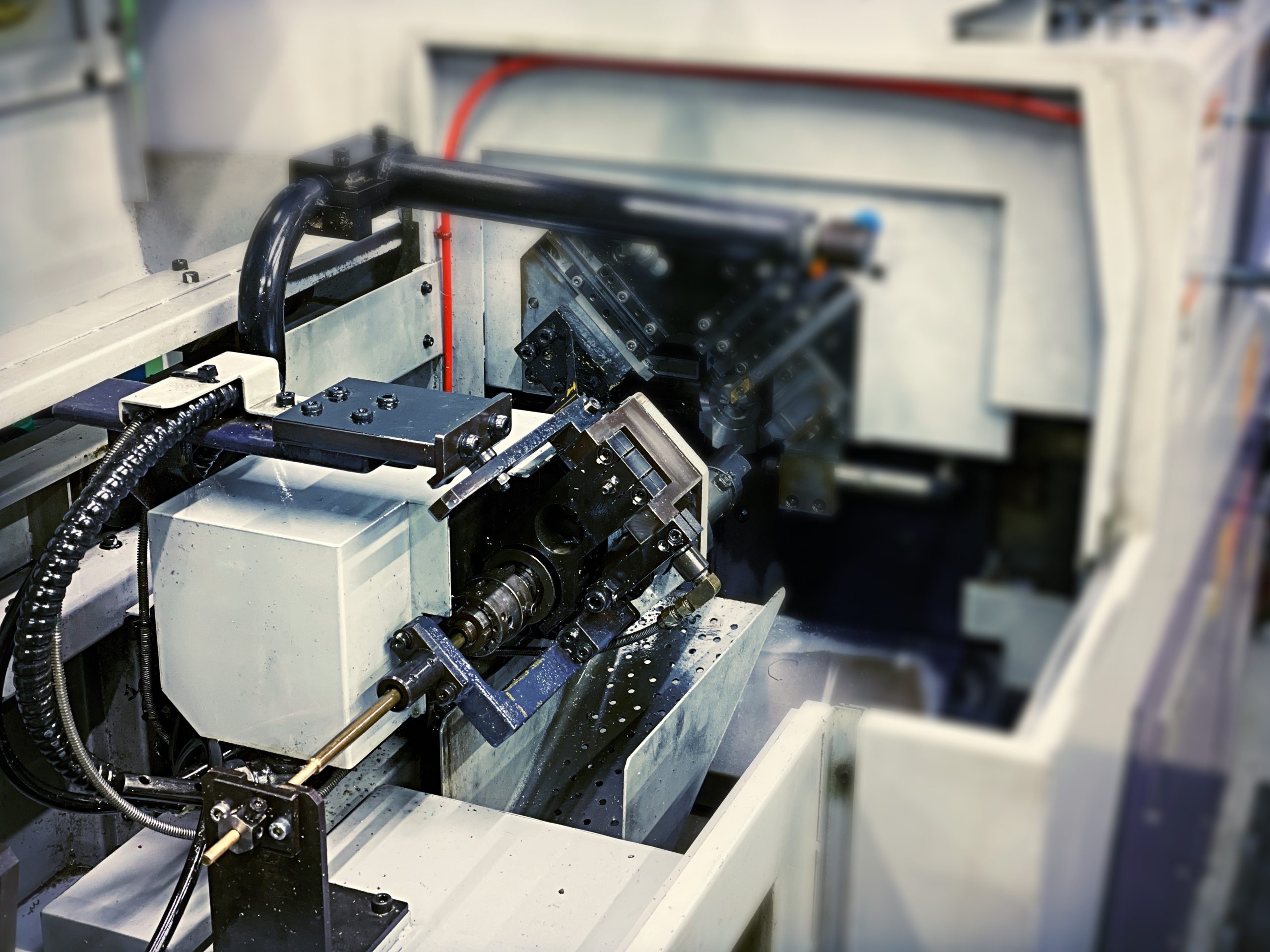

At Threeway Pressings, we use advanced pressing techniques to manufacture complex and intricate parts with tight tolerances, which allows us to ensure consistent results for a variety of specialisms.

The Key Benefits Of Metal Pressings UK

- Cost-Effective Production: Ideal for high-volume manufacturing with minimal material waste.

- High Precision & Consistency: Advanced tooling ensures uniformity across batches.

- Versatility: Suitable for various metals, including steel, aluminium, and stainless steel.

- Strength & Durability: Pressed metal parts maintain structural integrity under stress.

- Fast Turnaround: Efficient production processes reduce lead times.

Our Metal Presswork Capabilities

We offer a comprehensive range of metal pressing services, supported by state-of-the-art machinery and skilled craftsmanship.

Just some of these services include:

Progressive Die Stamping

Progressive die stamping is a high-speed process where a metal strip passes through multiple stations in a single press, with each station performing a different operation (e.g., punching, bending, or cutting). This method is perfect for producing intricate components with high repeatability.

Applications: Electrical contacts, automotive brackets, and precision washers.

Deep Drawing

Deep drawing involves forming sheet metal into hollow shapes by pressing it into a die cavity. At Threeway Pressings, we specialise in deep-drawn components, ensuring smooth finishes and structural integrity.

Applications: Enclosures, cans, and cylindrical housings.

Multi-Slide Stamping

Multi-slide stamping uses multiple tools working simultaneously to create complex, multi-dimensional parts. This technique is ideal for small, intricate components requiring tight tolerances.

Applications: Springs, clips, and connectors.

Fine Blanking

Fine blanking is a precision stamping process that produces clean, burr-free edges with exceptional accuracy. We employ fine blanking for parts requiring superior edge quality.

Applications: Gears, levers, and high-precision mechanical components.

CNC Press Brake Forming

For bending and shaping metal sheets, Threeway Pressings utilises CNC press brakes, ensuring precise angles and repeatability.

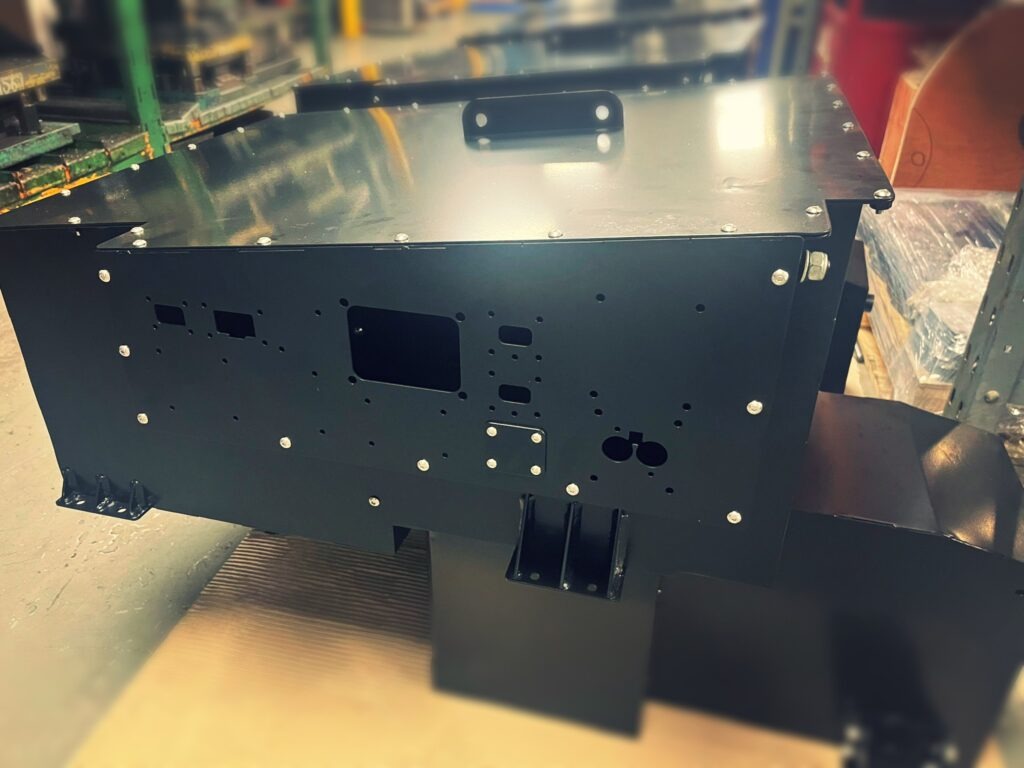

Applications: Brackets, chassis parts, and enclosures.

Assembly & Finishing Services

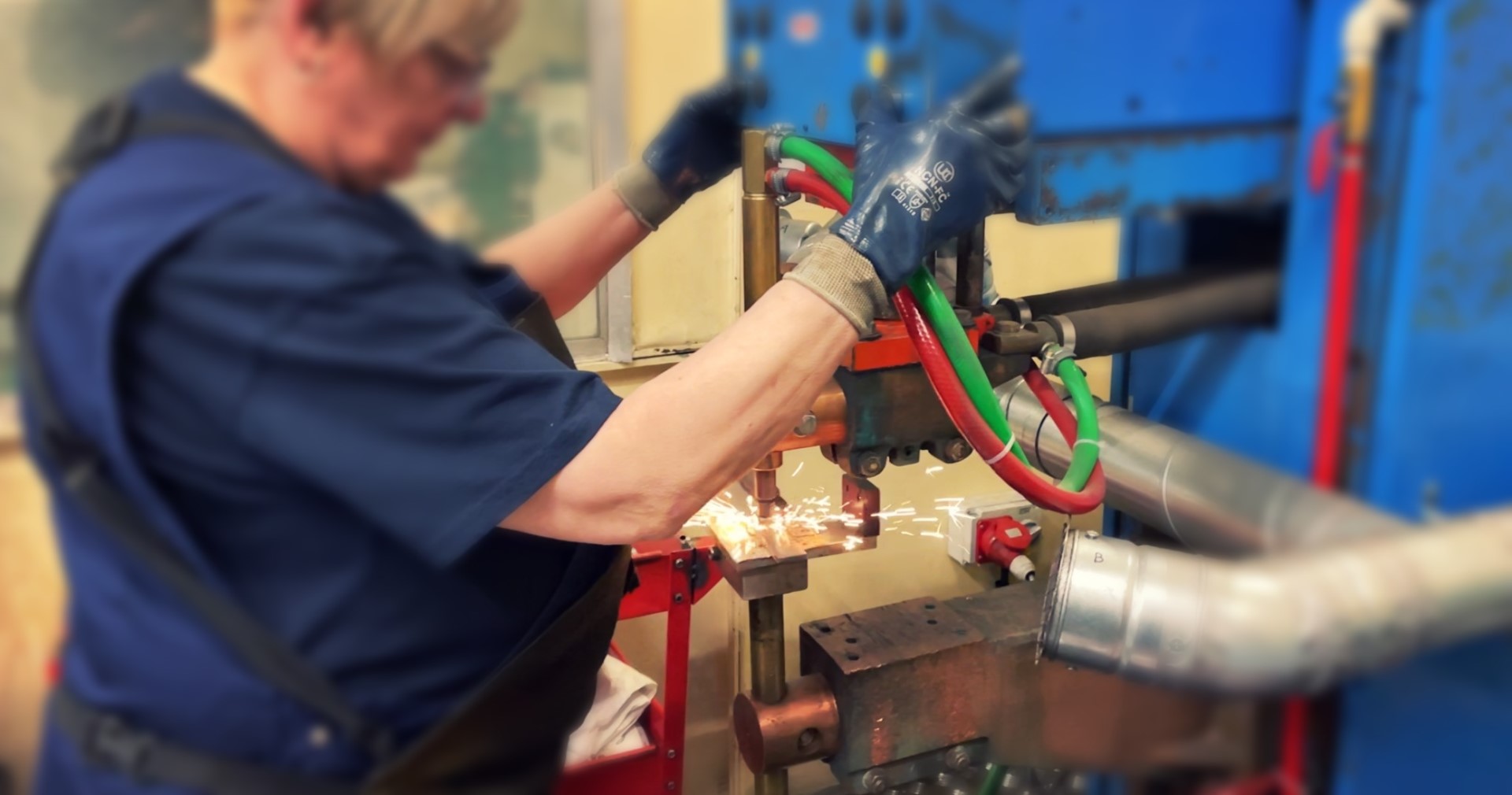

We provide secondary operations such as welding, riveting, powder coating, and plating to deliver fully finished components.

The Industries We Serve

At Threeway Pressings, we cater to a wide range of industries, delivering high-performance metal pressings that meet stringent quality standards. Sectors that we work with include:

Automotive

The automotive sector demands precision, durability, and cost-efficiency. We supply pressed metal parts such as:

- Brackets & mounts

- Exhaust components

- Seat mechanisms

- Fuel system parts

Aerospace

Aerospace components require strict adherence to safety and performance standards. We manufacture lightweight yet robust parts, including:

- Engine components

- Structural brackets

- Avionics housings

Medical

Precision and hygiene are critical in medical applications. At Threeway Pressings, we specialise in the production of:

- Surgical instrument parts

- Implantable device components

- Medical equipment housings

Industrial & Manufacturing

From machinery parts to enclosures, we support industrial clients with:

- Hydraulic components

- Conveyor system parts

- Electrical enclosures

Renewable Energy

As the renewable energy sector grows, we contribute to the move toward renewable energy sources by manufacturing:

- Solar panel frames

- Wind turbine components

- Battery housings

Why Choose Us For Metal Pressings UK?

At Threeway Pressings, we are proud to have an established reputation as a trusted partner for metal pressings.

Here are just some of the reasons why:

Experienced Engineering Team

Our expert engineers collaborate with clients from design to production, optimising parts for manufacturability and performance.

Quality Assurance

At Threeway Pressings, we competently adhere to ISO 9001 standards, implementing rigorous quality checks at every stage for defect-free components.

Custom Solutions

Whether prototyping or large-scale production, we tailor solutions to meet exact specifications, material preferences, and industry regulations.

Competitive Pricing & Fast Lead Times

By optimising production processes, we offer cost-effective pricing without compromising on quality or delivery schedules.

Our Metal Pressing Process

At Threeway Pressings, we use the following structured approach to provide consistent, high-quality services to all our clients:

- Consultation & Design Review: Understanding client requirements and refining designs for manufacturability.

- Tooling Development: Creating precision dies and moulds for pressing operations.

- Material Selection: Choosing the right metal (e.g., stainless steel, aluminium, or brass) based on application needs.

- Pressing & Forming: Executing stamping, deep drawing, or bending processes.

- Secondary Operations: Applying finishing treatments (e.g., welding, coating, or assembly).

- Quality Inspection: Conducting dimensional checks, stress tests, and surface inspections.

- Delivery: Shipping finished components on time, every time.

Choose Us For Top-Quality Results!

At Threeway Pressings, we are proud to be premier providers of metal pressings, offering expertise, precision, and reliability across many industries. Our commitment to quality, advanced manufacturing techniques, and customer-focused approach make us an excellent choice for businesses seeking high-performance metal components.

Whether for automotive, aerospace, medical, or industrial applications, we deliver tailored solutions that meet the highest standards. For more information or to discuss your metal pressing requirements, contact us today!