Injection Moulding Birmingham

Looking For Injection Moulding In Birmingham?

Make Sure You Contact Us!

At Threeway Pressings, we take pride in being the leading providers of injection moulding in Birmingham. We specialise in delivering high-quality injection moulding services that combine precision, durability, and cost-efficiency across a wide array of applications.

With extensive experience and cutting-edge technology, we serve multiple industries, producing products that meet the most demanding quality and performance standards!

What Do Injection Moulding Companies Do?

Injection moulding is a manufacturing process where molten material is injected into a mould cavity under high pressure.

As the material cools and solidifies, it takes the exact shape of the mould. This process is perfect for producing large volumes of consistent, precise parts, making it a preferred technique for mass production across sectors such as automotive, electronics, and consumer goods.

Its versatility and efficiency make injection moulding an essential choice for businesses requiring reliable, cost-effective manufacturing solutions.

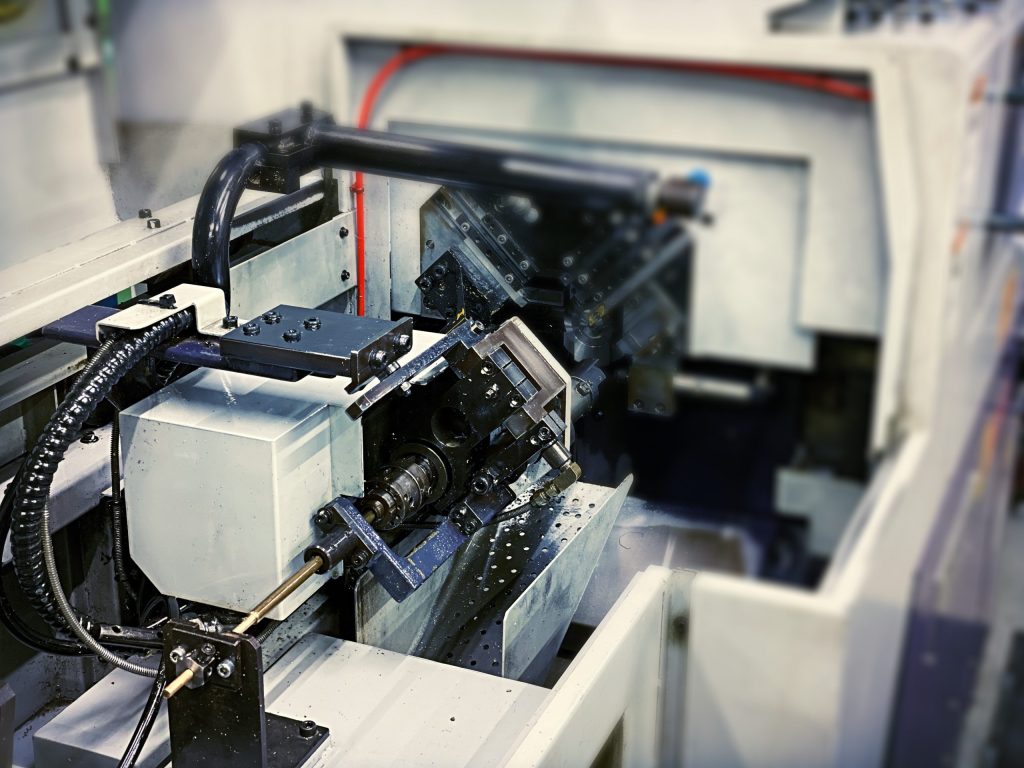

Our Expertise And Technology At Threeway Pressings

At Threeway Pressings, we operate a broad range of injection moulding machines, from small-scale tonnage to large, heavy-duty presses.

This versatility allows us to manufacture both small, detailed components and larger, more complex parts with ease. Our experienced team is highly skilled in working with a variety of materials including thermoplastics and elastomers, enabling us to recommend the best materials tailored to your specific project needs.

From initial tool design to material selection, we partner closely with you to ensure that every product is manufactured to the highest quality standards.

Our engineering experts provide valuable input right from the design stage, advising on mould design, material choices, and any other critical factors to ensure optimal product performance.

High-Quality, Cost-Effective Injection Moulding In Birmingham

Injection moulding excels in producing parts consistently and cost-effectively at scale.

At Threeway Pressings, our commitment to precision and quality control means we minimise waste and maximise efficiency across every project. Whether you require a few hundred pieces or millions of units, our services are tailored to deliver superior quality products at competitive prices.

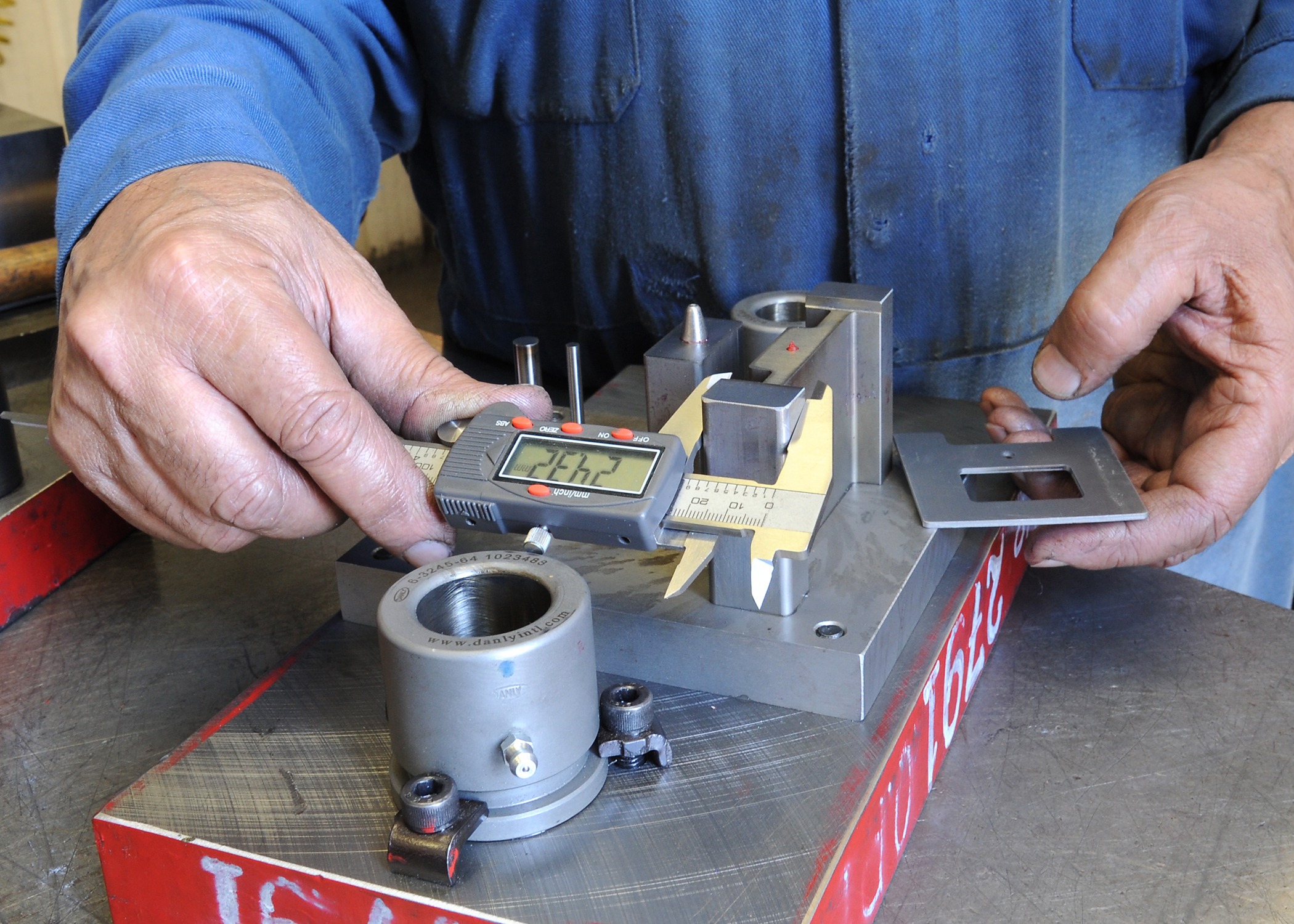

Our rigorous quality assurance processes involve detailed inspections throughout the production lifecycle—from prototype development to final manufacturing—to ensure that each part strictly adheres to your specifications and industry standards.

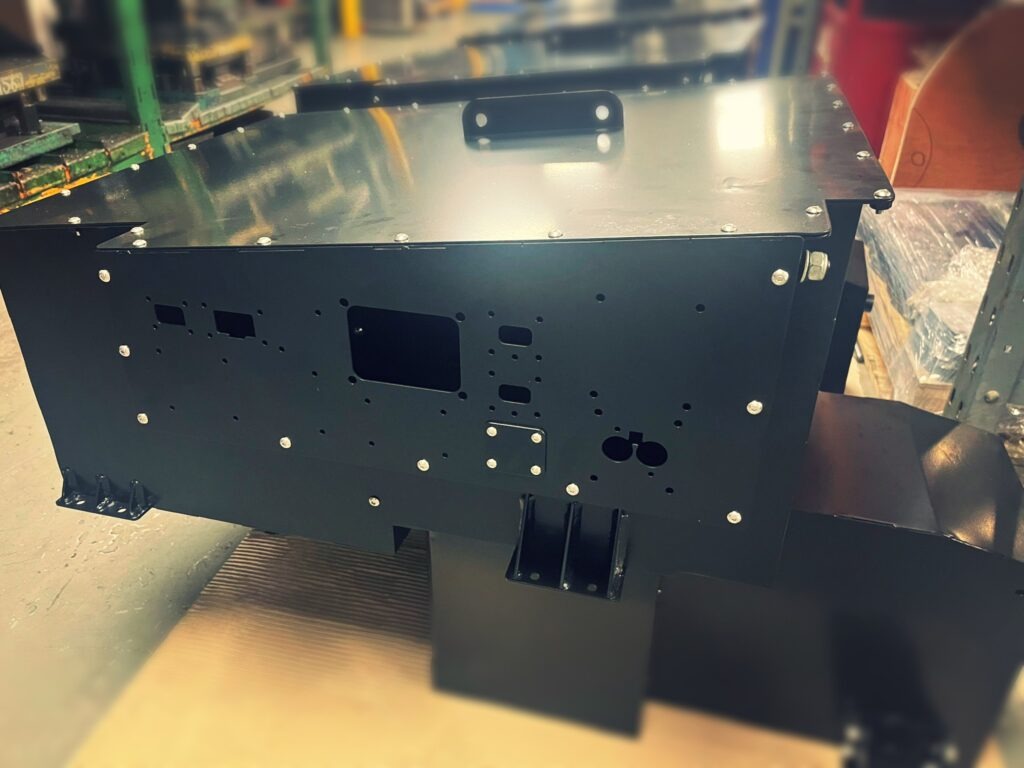

Custom Tooling And Mould Design

The versatility of injection moulding is largely due to the ability to create custom tooling and moulds tailored to specific needs.

Our in-house tooling department collaborates closely with our design and engineering teams to develop moulds that meet your exact specifications. We work with you to fully understand your project goals, ensuring every detail is incorporated into the design.

From initial concepts to prototyping, we assist in refining your product to optimise it for injection moulding. Our bespoke tooling processes ensure efficient manufacturing runs, helping reduce both production time and costs.

Overmoulding Capabilities

Overmoulding is a process where one material is moulded over another to produce composite parts. This technique is particularly useful for adding features such as grips or seals, and combining multiple materials in a single product.

At Threeway Pressings, we offer advanced overmoulding services that enable us to manufacture complex, multi-material components in one seamless process. This enhances both the functionality and aesthetic appeal of your products, making them more durable and versatile.

Whether you need overmoulded parts for automotive, medical, or consumer applications, our expertise ensures high precision and quality throughout.

Secondary Operations For Customisation

Beyond core injection moulding, we provide a range of secondary services that add significant value and customization options. These include insert moulding, laser engraving, and ultrasonic welding, which allow us to integrate logos, text, or assembly features directly into your parts, enhancing both functionality and appearance.

Laser engraving offers high-precision marking ideal for branding or part identification, while insert moulding enables the integration of metal or other inserts into plastic components to improve strength and durability. These supplementary services are fully integrated with our injection moulding process to deliver tailored solutions that meet your exact needs.

Sustainability And Material Selection

Sustainability is a key focus at Threeway Pressings, and our injection moulding processes reflect this commitment. We work with a wide variety of recyclable and environmentally friendly materials, ensuring that our manufacturing practices minimise environmental impact.

Our knowledgeable team can advise you on the most suitable material choices for your project, balancing cost-effectiveness, durability, and eco-friendly credentials.

We believe responsible material selection is essential to creating products that are not only high-quality but also environmentally conscious, helping you meet your sustainability targets without compromising performance.

The Industries We Serve

Threeway Pressings delivers expert injection moulding solutions across diverse industries, tailoring our approach to each sector’s specific demands. We proudly serve automotive, medical, electronics, consumer goods, and many other markets.

For automotive clients, we produce parts that meet rigorous standards for safety, performance, and durability.

In the medical field, our components comply with strict regulatory requirements to ensure safety and reliability.

In consumer goods and electronics, we focus on manufacturing visually appealing, high-quality products that improve user experience.

Choose Us For Injection Moulding In Birmingham!

There are several reasons why businesses trust Threeway Pressings for their injection moulding needs:

- Customisation And Flexibility: Whether you require a prototype or a large production run, our services are tailored to your needs.

- State-of-the-Art Technology: Advanced machinery and tooling enable us to produce precise parts with quick turnaround times.

- Cost-Effectiveness: Efficient production and competitive pricing deliver value without compromising quality.

- Rigorous Quality Control: Strict inspection processes ensure every part meets the highest standards.

- Expertise And Experience: Years of industry knowledge allow us to expertly handle diverse projects.

We offer comprehensive injection moulding services—from custom tooling and overmoulding to secondary operations and material advice—providing a complete solution to your manufacturing challenges.

Whether you need precision parts or high-volume production, Threeway Pressings is here to support your goals. Contact us today to discuss your project!