Metal Pressings Birmingham

Looking For Top-Quality Metal Pressings In Birmingham?

Make Sure You Contact Us!

At Threeway Pressings, we are proud to be Birmingham’s leading manufacturer of top-quality metal pressings, fabrications, and assemblies.

With decades of experience under our belt, we supply precision-engineered metal components tailored to meet the demands of a wide range of industries — from automotive and aerospace to medical and industrial sectors.

Our expertise in metal pressings ensures that you receive parts that are not only durable and accurate but also cost-effective, designed precisely to your specifications.

What Are Metal Pressings?

Metal pressings, often called metal stampings, refer to the process of transforming flat sheets of metal into specific shapes by using high-pressure presses and custom-designed dies. This manufacturing technique is especially efficient for producing large quantities of components that need to be consistent in quality and precision.

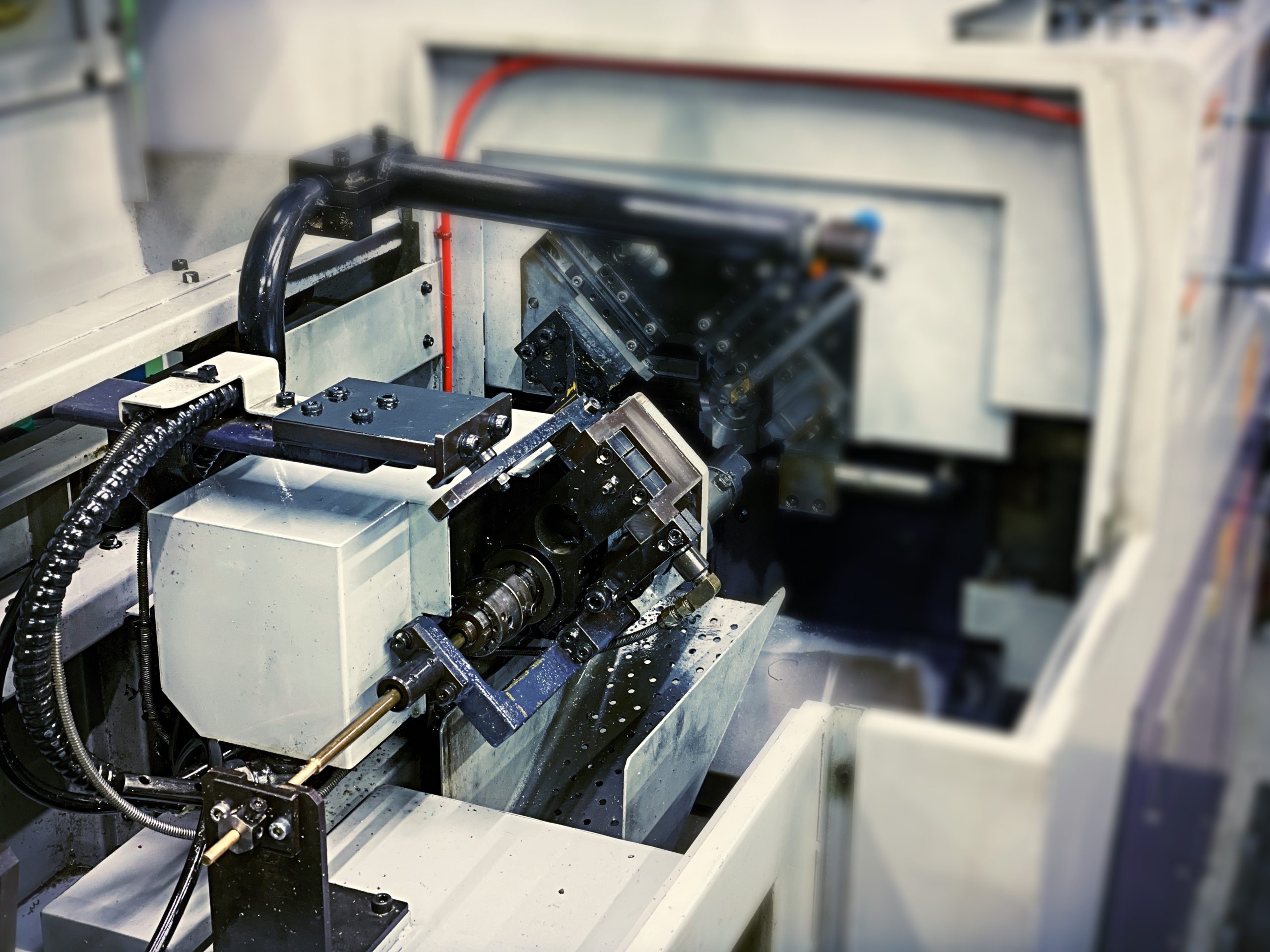

At Threeway Pressings, we harness advanced presswork technologies to create complex and detailed parts that meet very tight tolerances, guaranteeing consistent and reliable results across multiple industries.

The Key Benefits Of Metal Pressings

- Strength And Durability: Pressed metal components maintain excellent structural integrity, standing up to stress and wear in demanding environments.

- Versatility: We work with a variety of metals including steel, aluminium, and stainless steel, tailoring each project to the right material choice.

- Fast Turnaround: Our efficient processes help reduce lead times, getting your parts to you quickly without compromising on quality.

- High Precision And Consistency: Our state-of-the-art tooling ensures each batch of parts is uniform and meets exact specifications.

- Cost-Effective Production: Metal pressing is ideal for high-volume manufacturing, minimising waste while optimising material use.

Why Choose Us For Metal Pressings In Birmingham?

Our extensive capabilities, powered by modern machinery and skilled technicians, allow us to deliver a wide range of metal presswork services. Here are some key processes we specialise in:

Progressive Die Stamping

This fast and efficient method involves feeding a metal strip through multiple stations within a single press, each performing different actions like punching, bending, or cutting. It’s perfect for producing complex components quickly and consistently.

Applications: Electrical contacts, automotive brackets, precision washers.

Deep Drawing

Deep drawing forms hollow shapes from sheet metal by pressing it into a die cavity. We excel in deep drawing techniques to produce parts with smooth finishes and excellent structural strength.

Applications: Enclosures, cans, cylindrical housings.

Multi-Slide Stamping

Using multiple tools simultaneously, multi-slide stamping creates intricate, multi-dimensional parts with very tight tolerances, making it ideal for small, detailed components.

Applications: Springs, clips, connectors.

Fine Blanking

Fine blanking is a precision stamping process that delivers clean, burr-free edges and superior accuracy, crucial for parts that demand high edge quality.

Applications: Gears, levers, high-precision mechanical components.

CNC Press Brake Forming

For bending and shaping metal sheets, our CNC press brakes provide precise, repeatable angles for components like brackets and chassis parts.

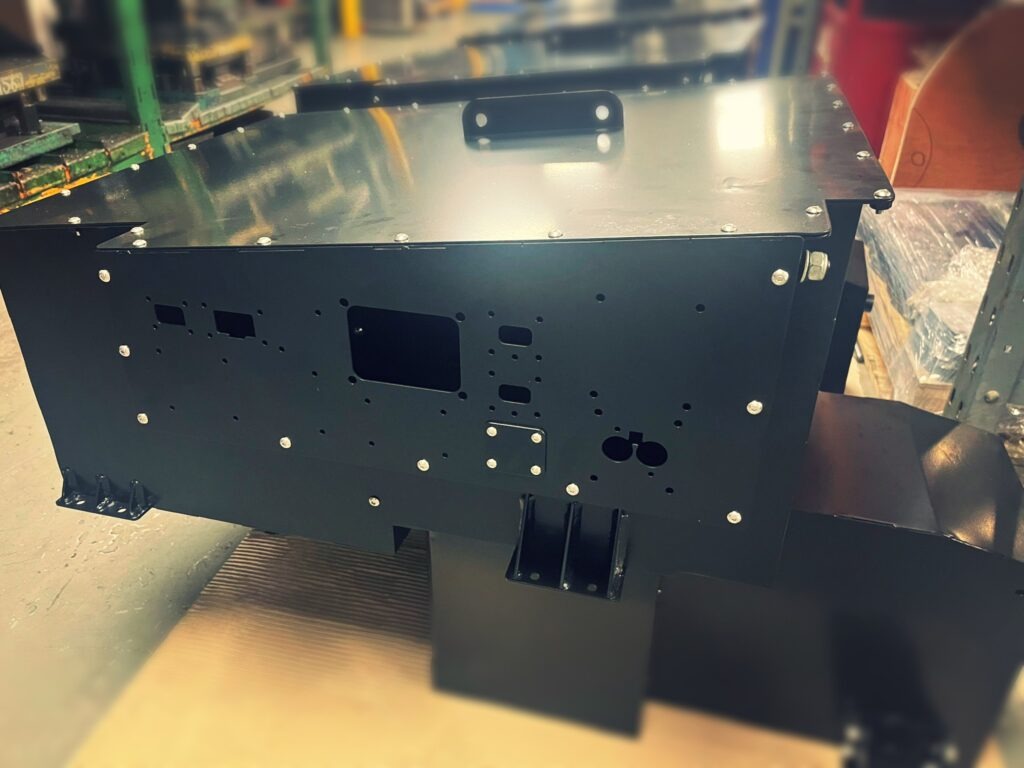

Applications: Brackets, chassis parts, enclosures.

Assembly And Finishing Services

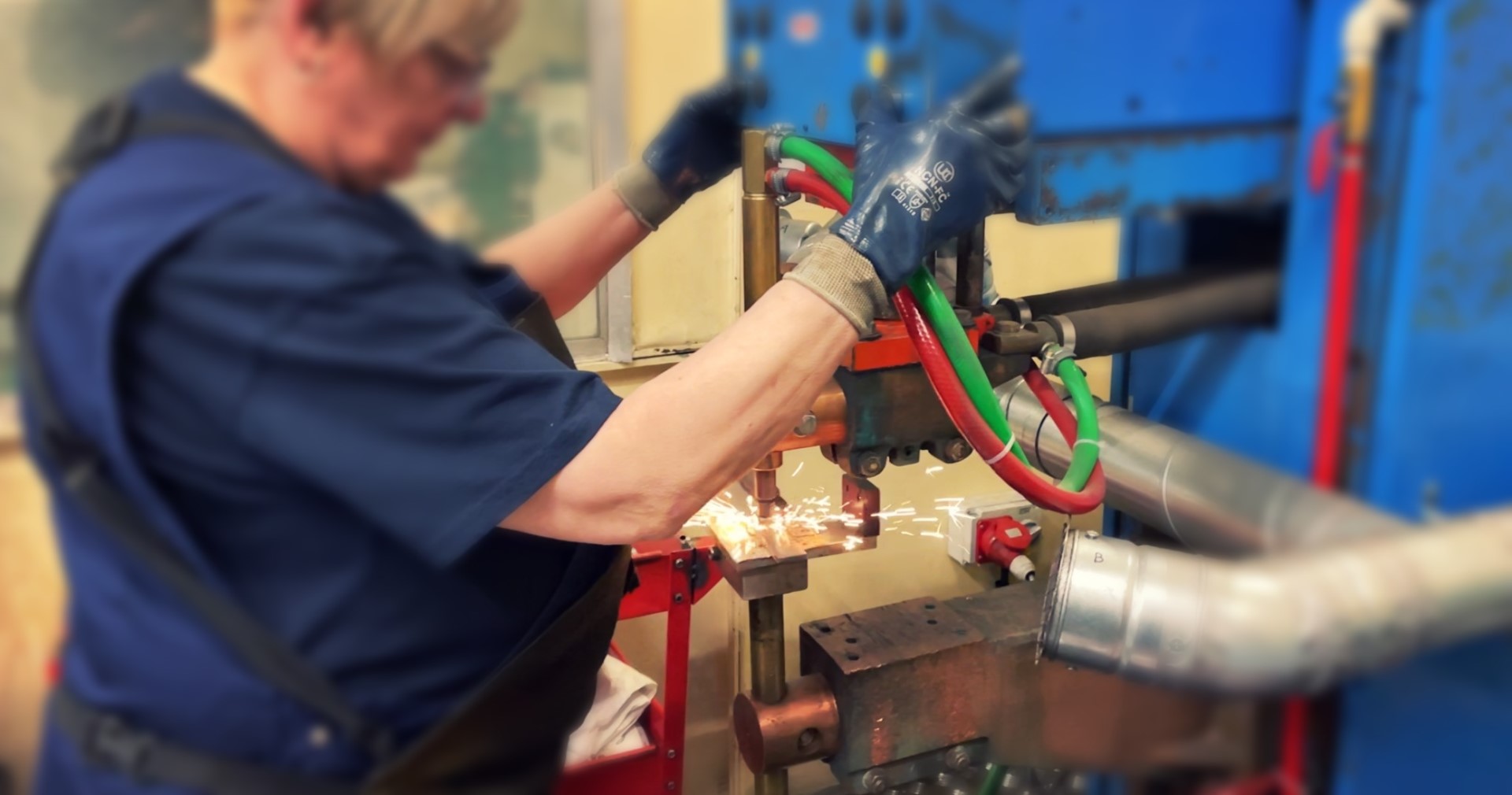

Beyond pressing, we offer secondary operations including welding, riveting, powder coating, and plating to deliver fully finished components ready for installation.

The Industries We Serve

Threeway Pressings proudly supports a wide variety of sectors, providing high-performance metal pressings that comply with strict quality and regulatory standards.

Here’s a selection of the industries we work with:

Automotive

Our automotive customers depend on us for precise, durable, and cost-effective components such as:

- Fuel system components

- Exhaust system parts

- Brackets and mounts

- Seat mechanisms

Aerospace

In aerospace, safety and performance standards are extremely demanding. We manufacture lightweight yet strong components like:

- Structural brackets

- Avionics housings

- Engine parts

Medical

Medical devices require precision and hygienic manufacturing. We specialise in producing:

- Implantable device components

- Medical equipment housings

- Surgical instrument parts

Industrial And Manufacturing

We support industrial clients with a range of metal parts including:

- Hydraulic system components

- Conveyor system parts

- Electrical enclosures

Renewable Energy

As the demand for renewable energy grows, we contribute by producing:

- Wind turbine components

- Solar panel frames

- Battery housings

Industry-Leading Capabilities

At Threeway Pressings, we have built a reputation as a trusted metal pressing partner. Here’s why companies choose us:

Custom Solutions

From one-off prototypes to large production runs, we tailor each solution to your exact specifications, materials, and compliance needs.

Experienced Engineering Team

Our engineers work closely with clients from concept to production, optimising designs for manufacturability and performance.

Advanced Manufacturing Facilities

We invest in modern presses, CNC machinery, and automated systems to deliver precision and efficiency on every project.

Quality Assurance

We follow ISO 9001 standards rigorously, applying thorough quality checks at every stage to ensure defect-free parts.

Competitive Pricing And Fast Lead Times

By streamlining processes, we offer competitive rates without sacrificing quality or delivery schedules.

How We Produce Top-Quality Metal Pressings In Birmingham

We use the following structured process to guarantee consistent, high-quality results:

- Consultation And Design Review: We start by understanding your project needs and refining designs to be manufacturable and efficient.

- Tooling Development: We create precision dies and moulds tailored to your pressing requirements.

- Material Selection: We help you choose the best metal—whether stainless steel, aluminium, brass, or others—based on your application.

- Pressing And Forming: Our skilled operators perform stamping, deep drawing, bending, or other forming operations with care.

- Secondary Operations: We add finishing touches such as welding, coating, or assembly to deliver complete components.

- Quality Inspection: Each batch undergoes dimensional checks, stress tests, and surface inspections to ensure perfection.

- Delivery: We ensure your parts are shipped promptly, so your project stays on track.

Choose Us For High-Quality Metal Pressings!

Threeway Pressings is proud to be your go-to supplier for expert metal pressings in the UK. With our combination of advanced technology, experienced team, and customer-focused service, we deliver precision, reliability, and value for a wide array of industries.

Whether your project is in the automotive, aerospace, medical, or industrial sectors, we provide custom metal pressing solutions that meet the highest standards. To discuss your requirements or get a quote, contact us today—we’re ready to help you bring your ideas to life!