Injection Moulding Companies

Need A Top-Quality Injection Moulding Company?

Make Sure You Contact Us!

At Threeway Pressings, we are proud to be one of the UK’s leading injection moulding companies.

With years of experience and cutting-edge technology, we create high-quality, durable, and cost-effective moulded products for a wide range of industries. Our focus is on precision and performance, ensuring every product meets the highest standards!

What Do Injection Moulding Companies Do?

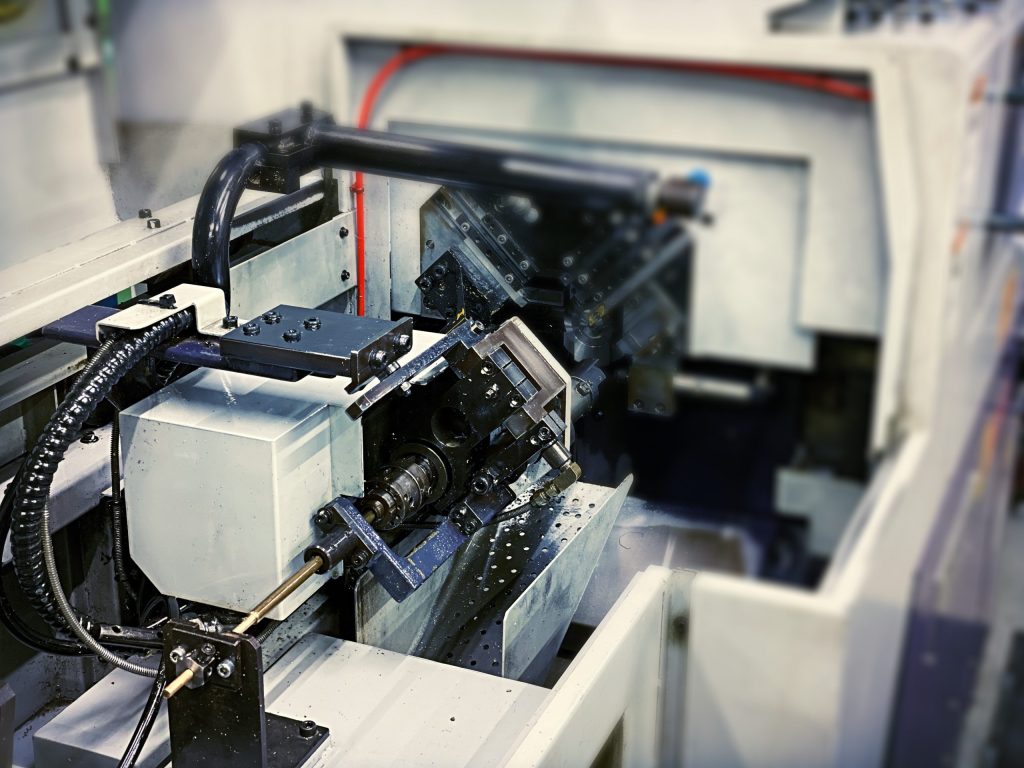

Injection moulding is a process where molten material is injected into a mould under high pressure. The material solidifies as it cools, taking the shape of the cavity.

This method is ideal for producing large volumes of precise and consistent parts, making it a go-to choice for industries such as automotive, electronics, and consumer goods.

Its versatility and efficiency make injection moulding an essential process for companies needing high-quality, cost-effective manufacturing solutions.

Why Choose Us To Be Your Injection Moulding Company?

Our range of injection moulding machines – from small to large tonnage – enables us to manufacture everything from intricate components to larger, complex parts.

Our highly skilled team works with various materials, including thermoplastics and elastomers, ensuring we can provide the best options for your specific needs.

From tool design to final production, we collaborate with you to create high-quality, reliable products; our engineers will guide you through every step, optimising mould design, material selection, and production processes for the best possible results!

Excellent Results Every Time

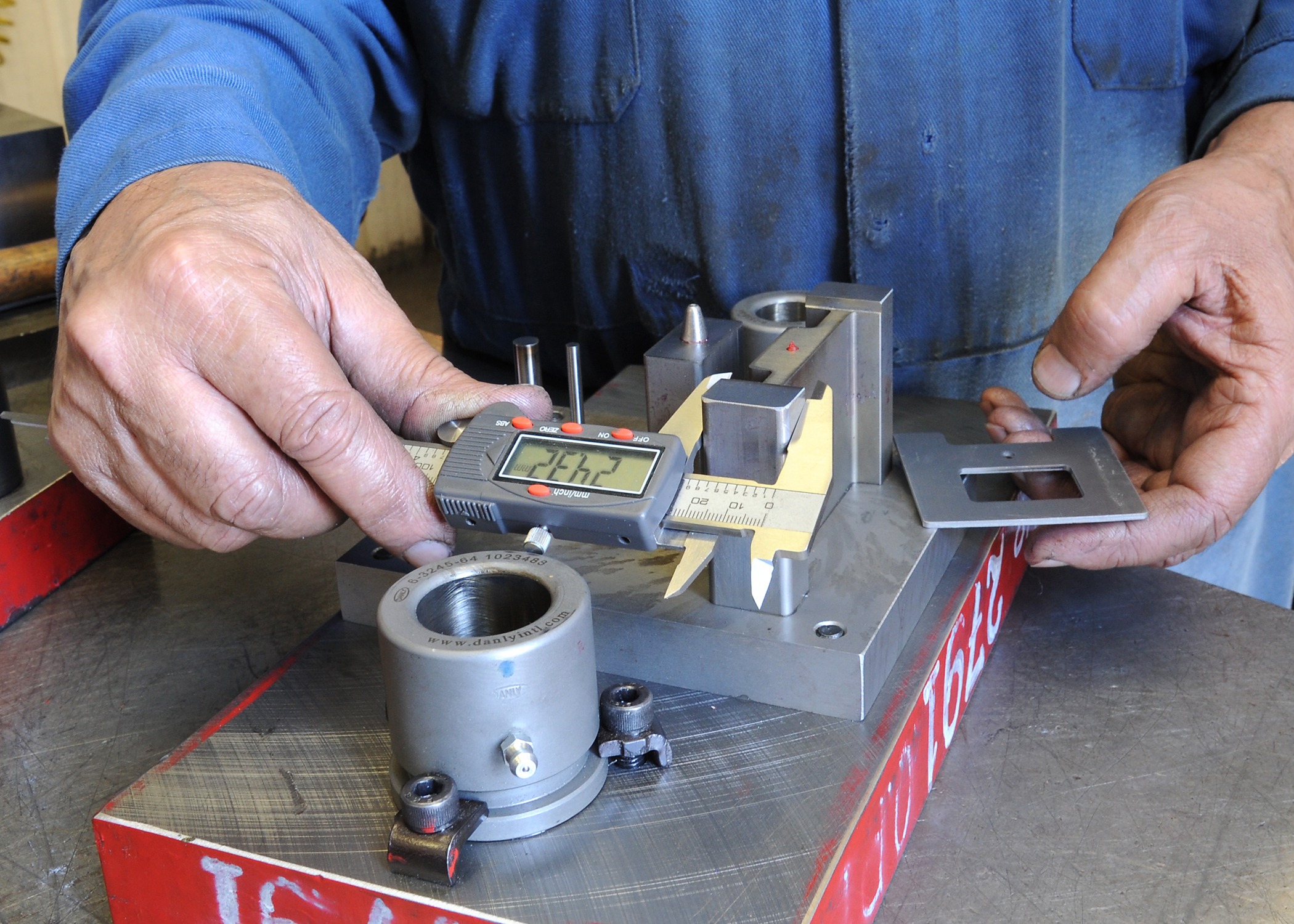

With injection moulding, we can produce high volumes of diverse parts that are consistent in quality, making the process both versatile and highly reliable.

At Threeway Pressings, our team focuses on precision and efficiency, reducing waste and maximising cost-effectiveness. Whether you need a few hundred or several million units, our streamlined processes ensure you’ll receive high-quality components at competitive prices.

Plus, we maintain strict quality control at every stage, from prototyping to final inspection, ensuring all parts meet the highest industry standards and the required specifications.

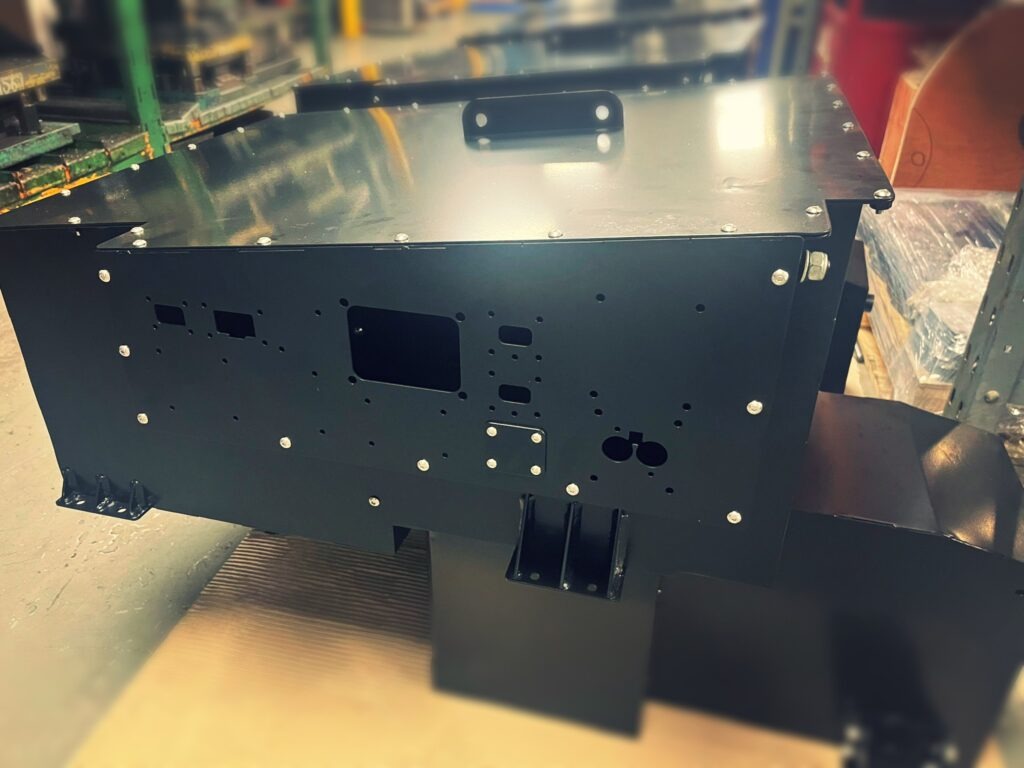

Custom Tooling And Mould Design

What makes injection moulding so versatile is the ability to create custom tooling and moulds.

Our in-house tooling experts work closely with our design and engineering teams to develop high-quality moulds, ensuring smooth, efficient production. From initial concept to prototyping, we help refine your product for the best possible results.

With precision tooling and efficient manufacturing, we help reduce costs and production time while maintaining exceptional quality!

Overmoulding Capabilities

The process of overmoulding, where one material is moulded over another, can create multi-material components with added functionality. This is perfect for items that require additional features, such as seals or soft grips.

At Threeway Pressings, we offer advanced overmoulding capabilities, allowing us to manufacture durable, aesthetically refined parts in a single process.

Whether for automotive, medical, or consumer products, we will tailor our approach to suit your requirements.

Secondary Operations For Customisation

In addition to injection moulding, we offer a range of secondary options to enhance your products, increasing their functionality and customisation.

These include:

- Insert Moulding – i.e. Embedding metal inserts within plastic components for added strength.

- Laser Engraving – i.e. Adding branding, serial numbers, or assembly elements.

- Ultrasonic Welding – i.e. Creating strong, seamless joins.

These additional services allow us to deliver complete, ready-to-use components tailored to your precise needs.

Sustainability And Material Selection

Sustainability is a core part of our approach. We use recyclable and eco-friendly materials wherever possible, helping our clients make responsible choices without compromising performance.

We believe that responsible material selection is vital – our team will advise you on the best choice to meet your environmental and functional requirements, ensuring a balance of durability, cost-effectiveness, and sustainability.

The Industries We Serve

We provide high-quality injection moulding solutions for a wide range of industries, including:

- Medical – We produce reliable and compliant parts for healthcare applications.

- Automotive – We can create precision-engineered components built for durability and performance.

- Consumer Goods – Our moulds ensure aesthetic, functional products for everyday use.

- Electronics – Our high-quality casings and components for electronic devices guarantee quality products every time.

Each industry has unique requirements, and we tailor our solutions to meet the highest standards in every sector.

Choose Us As Your Injection Moulding Company!

The following are just some of the benefits we offer our clients:

State-of-the-Art Technology – Advanced machinery and tooling for precision manufacturing.

Expertise & Experience – Years of industry knowledge and technical skills.

Customisation & Flexibility – Tailored solutions for projects of all sizes.

Rigorous Quality Control – Stringent processes to ensure optimum results.

Cost-Effective Production – Efficient processes for competitive pricing.

Short Lead Times – We save our customers time and money!

At Threeway Pressings, we are proud to offer sophisticated injection moulding solutions for many industries. From custom tooling and overmoulding capabilities, to secondary operations and material selection, we provide a complete service to meet your manufacturing needs.

Whether you need precision components or large-scale manufacturing, we are here to help.